This product is not available for new orders. We recommend ordering: SunSentry.

Resumen

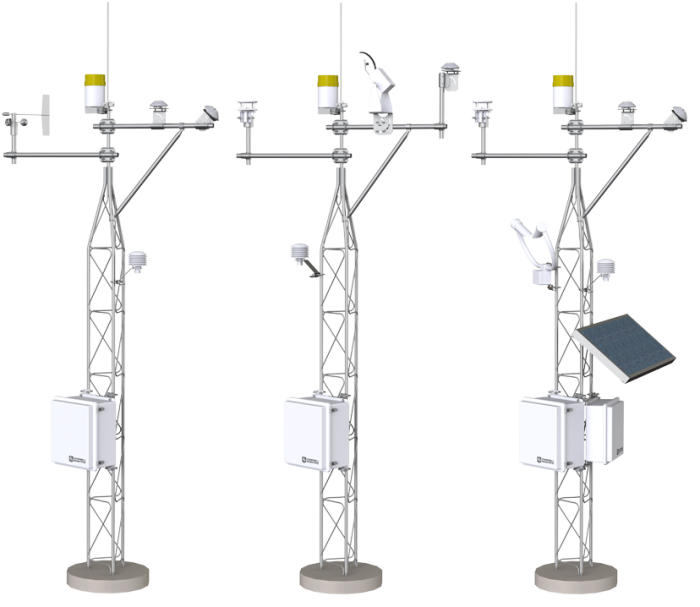

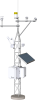

The Solar1000 is an automated data-acquisition system specifically designed for solar monitoring applications. The standard package is designed to meet CaISO standards with AESO variants available. Systems are easily customized with accessories for every aspect of the station, from communications to mounting options.

Typical applications include pre-construction phase solar resource assessment, baseline data collection, and performance monitoring. The Solar1000 simplifies the process of collecting system data by acting as the single point data gateway for environmental, inverter, and meter data.

Medidas

La mayoría de los sistemas que fabricamos son personalizables. Sin embargo, estos sistemas, en la mayoría de los casos miden los siguientes parámetros:

- Temperatura del aire

- Solar radiation - global horizontal (GH)

- Solar radiation - plane of array (POA)

- Surface temperature - back of panel

- Dirección viento

- Velocidad viento

- Precipitación

- Presión barométrica

Ventajas y características

- Contiene un datalogger Campbell Scientific CR1000

- Mide sensores de radiación basados en termopilas

- Realiza la medida mediante termopar en la parte trasera del módulo

- Incluye conectores sellados circulares en la parte exterior del armario, lo que simplifica la conexión del sensor

- Su diseño integrado con cableado y programación ya incluidos, reducen el tiempo en la puesta en marcha

- Soporta Dynamic Host Configuration Protocol (DHCP) e IP estática

- Incluye batería de backup que permite que la estación siga adquiriendo datos aunque haya cortes en la alimentación eléctrica o fallos en la red de comunicaciones

- Actúa como un gateway de datos para equipos medioambientales, inversores o medidores

- El diseño modular facilita la personalización del sistema

- La compatibilidad con Modbus, CanBus y DNP 3.0, facilita la integración

Imágenes

Preguntas frecuentes

Número de FAQs relacionadas con Solar1000: 6

Expandir todoDesplegar todo

-

The solar sensors should be cleaned daily—at the minimum, weekly. The required maintenance cycle varies based on location, precipitation, and biologic activity. Desiccant should be changed on a regular interval, but that interval depends on ambient environmental conditions.

-

Yes. The Solar1000 has been designed to meet California ISO specifications.

-

No. The main concern when installing the system is to ensure that the stand is secure to the ground and that the sensors are aligned and leveled. With patience, these tasks can be performed fairly easily.

-

The CR1000 datalogger has built-in capabilities to be fully compatible with Modbus, as well as DNP3. The intention is to add additional compatible protocols as the industry and markets change and evolve.

-

Unless the panels are tracking either in one axis or two, it is not likely that a tracker and pyrheliometer are needed.

-

The Solar1000 is both a station for resource assessment and power performance for photovoltaic power production facilities. For example, this system may be used to quantify the potential power that could be generated at a proposed site. During and after construction at a site, the station can be used to provide data that isolates system inefficiencies and provides crucial information to funding agencies.