Calibration Essentials: Frequency (Calibration Intervals)

por Michael Jacobs | Actualizado: 04/01/2024 | Comentarios: 1

In our two previous calibration blog articles, we explored the vital role of calibration in ensuring the accuracy and reliability of measurement instruments across diverse fields. We delved into the fundamentals of calibration, its various methods, and the importance of metrological traceability. Now, we turn our attention to this critical question: How often should you calibrate your devices?

|

Recommended for you: If you missed either of our first two calibration blog articles, take a moment to read them now: |

Regardless of the industry or field of science you work in, regular calibration plays a pivotal role in ensuring measurement device accuracy and reliability. It involves establishing a relationship between the output of a Device Under Test (DUT) and a traceable reference standard, allowing users to assess the device's performance, identify any discrepancies, and/or validate past measurements. Determining the appropriate calibration interval (frequency of calibration) is crucial to maintain data integrity and ensure continuously reliable measurement results.

What factors influence how calibration intervals are determined?

Several factors should be considered when determining the calibration frequency, including:

- Device Type: The type of measurement device contributes to its susceptibility to drift and other environmental factors. For instance, instruments such as relative humidity (RH) probes or pressure gauges may require more frequent calibration than robust devices like DC power supplies.

- Application: The measurement device’s intended use significantly impacts calibration frequency. Devices used in critical applications, including medical diagnostics and industrial processes, demand more frequent calibration.

- Environmental Conditions: The environment where the measurement device operates plays a role in calibration frequency. Devices exposed to temperature, humidity, or vibration fluctuations may require more frequent calibration.

- Manufacturer Recommendations: Manufacturers typically provide guidelines for calibration frequency based on the device's specifications and intended use. These recommendations should be considered in determining calibration schedules.

- Device History: Calibration data for a specific piece of equipment can be used to optimise a calibration interval. This may mean lengthening the interval for a device with a long history of little drift or shortening the interval where equipment has been found Out of Tolerance (OOT).

- Quality Policy: Some quality systems require more frequent calibration of measurement devices.

Who is responsible for determining a device’s calibration interval?

Ultimately, the end user or owner of the equipment is responsible for determining a device’s calibration interval. They are the most familiar with the above factors to consider and best understand their organisation’s risk tolerance for a possible OOT condition. Calibration service providers may recommend intervals and even offer tools to analyse a device’s history to optimise the interval. However, to avoid any perception of a conflict of interest, a service provider should not set the interval without input from the end user/owner.

Calibration Records and Documentation

At a minimum, the following information should be contained in a calibration certificate:

- Device Identification: A unique identifier for the device being calibrated. This can include the manufacturer and model number, serial number, or a unique asset number.

- Calibration Date: The date the calibration was performed

- Procedure Used: An identifier of the standardised calibration procedure

- Calibrating Entity: Identification of the calibration laboratory where the calibration was performed

- Adjustments Made: If any adjustments were made to the device, a detailed description of the adjustments should be documented.

- Statement of Conformity: A statement that describes compliance to a recognised standard

- Calibration Report: A report with measurement results and uncertainties should also be included.

Calibration records should be stored securely and be accessible for future reference. These records provide valuable information for trending, troubleshooting, ensuring compliance with regulatory requirements, and maintaining a high level of quality control.

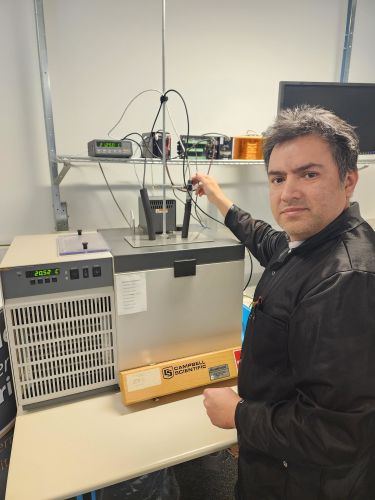

Campbell Scientific Calibration Services

Recognising the importance of accurate and reliable measurements, Campbell Scientific offers comprehensive calibration services for a wide range of environmental monitoring equipment. Our experienced technicians use traceable standards and follow stringent procedures to ensure your devices meet the highest performance standards. You can choose from factory calibration or convenient field calibration services, depending on your needs and the type of equipment you have. Campbell Scientific offers flexible solutions to ensure your data integrity and peace of mind.

Conclusion

Calibration frequency is an essential consideration for verifying the accuracy and reliability of measurement devices. By understanding the factors influencing calibration frequency and adhering to established guidelines, organisations can maintain the integrity of their measurement processes and ensure operational safety, quality, and efficiency. With reliable calibration partners such as Campbell Scientific, you can be confident in your data.

I hope this article has deepened your understanding of how important it is to set a regular calibration frequency that meets your needs. In the next blog article in this series, we’ll take a closer look at drift and its impact on your measurements. If you have any questions or comments, please post them below.

Credits: Ramatoulaye Nabi of Campbell Scientific contributed to this article.

Michael Jacobs was the Manager of Calibration and Repair Services at Campbell Scientific, Inc. With expertise in DC/low-frequency measurements, he analyzed measurement uncertainty and quality standards such as ISO 9001, ISO 17025, ANSI Z540, and relevant JCGM documents. Michael was trained in the US Air Force Precision Measurement Equipment Laboratory AFMETCAL program and had more than 30 years’ experience in measurement science.

Michael Jacobs was the Manager of Calibration and Repair Services at Campbell Scientific, Inc. With expertise in DC/low-frequency measurements, he analyzed measurement uncertainty and quality standards such as ISO 9001, ISO 17025, ANSI Z540, and relevant JCGM documents. Michael was trained in the US Air Force Precision Measurement Equipment Laboratory AFMETCAL program and had more than 30 years’ experience in measurement science.

Comentarios

MollyNishid | 08/28/2024 at 09:50 AM

Recently, I was faced with the problem of where to spend my time without leaving home - I kept looking for reliable gaming platforms, but every time I hit a dead end. The disappointment was incredible, because it is not so easy to find a place where you can really enjoy the game. But after a long search, I came across the Mostbet platform https://mostbet-free-spins.com/ which really deserves attention. It is a universal platform that works under a Curacao license, which already speaks of its reliability. In addition, Mostbet is regularly checked by independent auditors, which adds even more confidence to the choice. The feedback from players, both newcomers and regular users, is mostly positive, and this is another plus. Personally, what attracts me the most is the variety of games - from classic options to games with live dealers from leading developers.

Please log in or register to comment.